Scenario struck for back several years gassalarm after several incidents with acetylene-gas. The authority believed many companies are sloppy with training in gassbruk, and thus made themselves guilty of offences.

New figures from the labour Inspection authority may indicate that the situation has not been particularly better in the day.

They have conducted 1575 supervision in the last three years, such as training and information related to the kjemikaliehåndtering.

Here found kontrollørene a breach of the rules in 51 per cent of the cases.

– This is a too-high number, and is something we’re looking seriously at. It may indicate that many employers take this lightly, and have too little knowledge about the dangers, ” says yrkeshygieniker Anne Marie Lund Eikrem in the labour inspectorate.

the Big unknown

13. June was several buildings in the city were evacuated after a bottle with the gas acetylene caught fire on a construction site in the middle of the city centre.

the Same month, there were at least three other events around the country, where acetylenflasker has begun to burn.

the Explosion was over after the specially trained shooter had a loose five shots against the burning gas cylinder. You need javascript to see the video.

the Explosion was over after the specially trained shooter had a loose five shots against the burning gas cylinder.

Read also: Police use great resources on the unstable gas cylinders – 19 fires in three years

From 2011 until today has also the labour Inspection authority recorded 9 accidents where it is used acetylengass.

– Three of the accidents resulted in injury, and six accidents without injury, ” says yrkeshygieniker Anne Marie Lund Eikrem in the labour inspectorate.

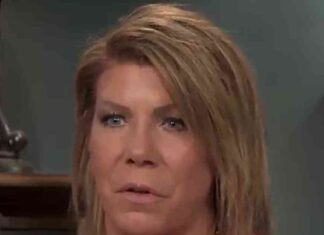

Anne Marie Lund Eikrem in the labour inspectorate.

Photo: Private

She emphasizes that the labour inspectorate does not receive notice of all accidents with serious damage. Incomplete reports could lead to the big unknown in kjemikalieulykker.

– There is a relatively large proportion of accidents with non-fatal injuries where it is not filled out if chemicals are involved or not.

Here you see the rest of the overview of the discrepancies and offences the audit found:

Can lead to long-term injuries

Such differences can not only lead to explosions, and immediate injuries, but also more long-lasting consequences.

– It is not only the risk for acute events such as blasts that increase at unsustainable kjemikaliehåndtering. In the long term this can also lead to serious diseases, such as cancer, ” says Eikrem in the labour inspectorate.

Labour’s response to such offences can be anything from orders to legal reports.

In addition, the driver of the preventive measures that veiledningsaktiviteter.

– We work to increase knowledge in the business, and to get them to them to understand why and how they are going to work preventive and systematically with the HSE.

Should have a mandatory certificate

Berit Sørset is fagsjef director and assistant director in the Norwegian Industry.

Datterorganisasjonen Northern Entreprenørers Service Organisation (NESO) has around 130 member companies with about 5,000 employees, where more jobs with the hot work.

She tells us that the companies who work with this have the required certificates to assure that they can their cases.

Berit Sørset, fagsjef in the Norwegian Industry.

Photo: Norwegian Manufacturing

– I contacted one of our member companies, who say that all who work with hot work, i.e. including welding, shall have a hot work certificate. It is mandatory. In the training included the use of bottles, equipment, type of gases and fuse, with more.

brigade commander Tor Arne Elvrum in the Oslo fire – and redningsetat has the following advice to minimise the risk of kjemikalieulykker.

– Fixed storage space, good branding, good user training and early warning in case of fire.